General Industry Fall Safety Standards

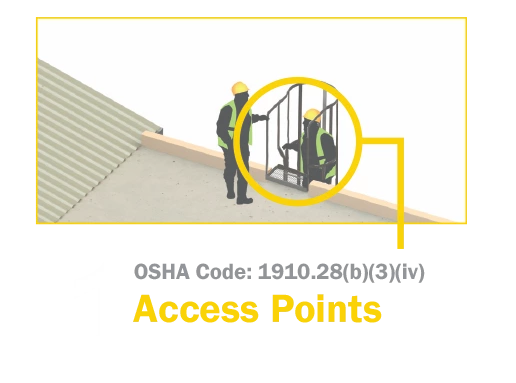

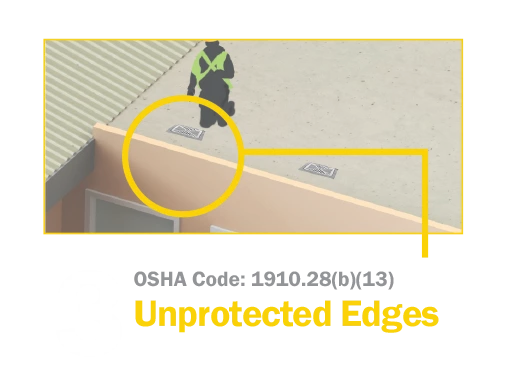

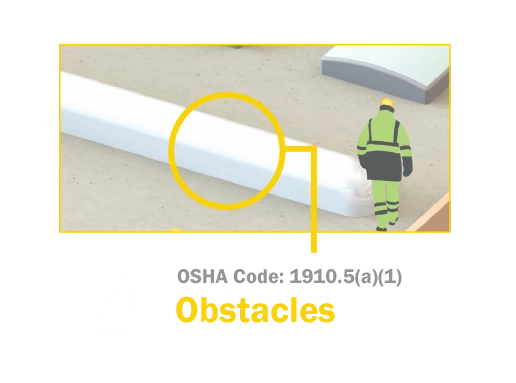

Comprehensive standards for individuals responsible for ongoing maintenance, including regular inspections, repairs, and accessing elevated areas.

While construction codes strictly govern activities carried out during the erection or renovation of a structure, General Industry codes extend beyond those phases to encompass ongoing maintenance and operation. This guide will focus solely on the nuances of the General Industry code, shedding light on the specific regulations governing fall protection for individuals involved in the long-term maintenance and functionality of a building.

Furthermore, the guide acknowledges that while construction codes primarily regulate activities during structure erection or renovation, General Industry codes have a broader scope that includes continuous maintenance and operation. This resource will specifically delve into the intricacies of the General Industry code, providing clarity on the distinct regulations that dictate fall protection for individuals engaged in the sustained maintenance and optimal functioning of a facility.