Revolutionizing Safety Systems

The Superiority of Kee Klamp Fittings over Fabricated Railings

Kee Klamp fittings can be used in a variety of settings, including residential, commercial, and industrial projects. They are ideal for outdoor railings, balconies, stairways, and more. The versatility of these fittings makes them a popular choice for DIY enthusiasts and professional contractors alike.

Another advantage of Kee Klamp fittings is their ease of customization. They can be combined with a variety of tubes and pipes to create a unique railing design that fits the specific needs of each project. This level of customization allows for complete control over the look and functionality of the railing.

Overall, Kee Klamp fittings offer numerous benefits, making them a top choice for railing projects. From their ease of installation and customization to their durability and affordability, Kee Klamp fittings are the perfect solution for all your railing needs.

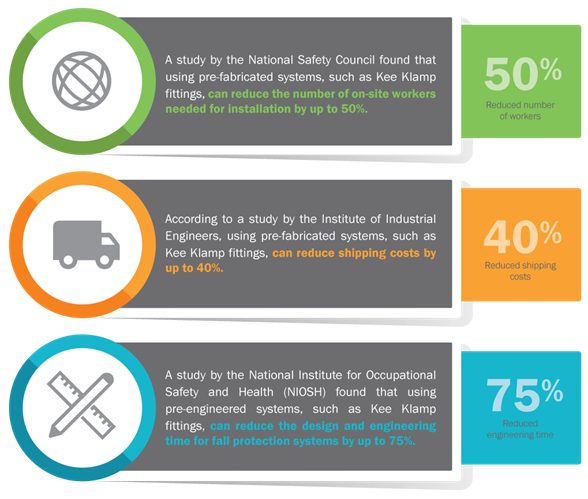

Easy Assembly: Kee Klamp is a simple and easy-to-use system for building structures, suitable for DIY and inexperienced users, due to its no-welding and no-threading design, and its quick assembly through a slide-and-lock mechanism.

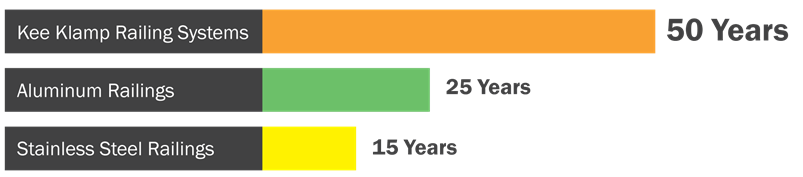

Durability: Kee Klamp components are made of galvanized steel, making them durable and resistant to rust and corrosion.

Cost Efficiency: Kee Klamp allows for cost savings and reuse of parts by allowing purchase of only what's needed for a project, instead of pre-manufactured products.

Versatility: Kee Klamp is versatile for building various structures, both indoor and outdoor, from simple to complex.