ADA Compliant Railings

Designed to provide a smooth and continuous handrail that complies with ADA OSHA regulations

The surface of the handrails is smooth, and the user can maintain a consistent grip and easily run their hand along the entire handrail.

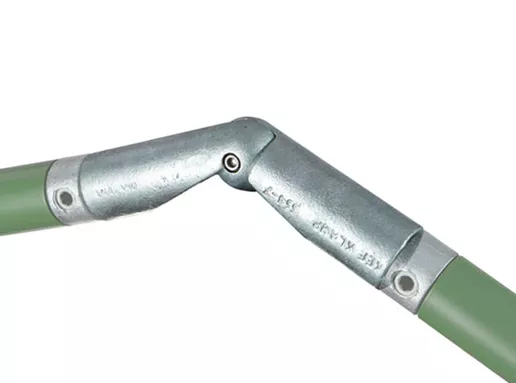

Our unique fittings allow our ADA railings to be custom designed to fit all ranges of ramp design from standard, to very complicated.

Our team will help guide you with design and installation, ensuring that your handrail is safe and ADA compliant.

Because our ADA handrail does not require any welding, it can be easily installed on-site with a few common tools.

The handrail must be located on both sides of the stairway or ramp and it must be a consistent height (between 34 and 38 inches) above the walking surface. There also needs to be at least 36 inches of space between the two railings to allow wheelchairs and people to pass through. It’s the ideal choice for all new build and refurbishment projects.

Kee Klamp Access Disability Railing’s range of tubular fittings is designed specifically to meet the requirements of the Americans with Disabilities Act. So you can rest assured you are choosing a fully compliant railing system.

These fitting enable the railing to be smooth and continuous.

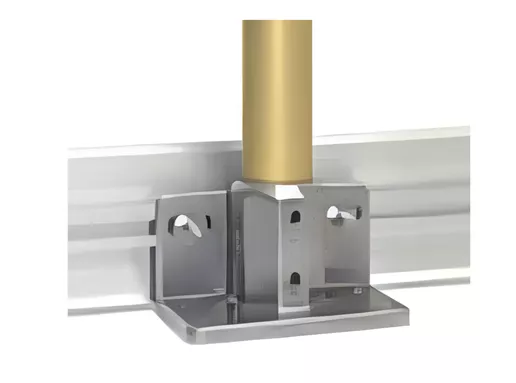

This fitting is used frequently in the system. It allows the fitting to be placed in line with the pipe railing.

These fittings are designed to couple together with the pipe and internal couplings to form a complete smooth-rail system.

These fittings cradle the pipe so that the railing can pass over the fitting uninterrupted. Small tek-screws hold the railing in place.

Schedule 40 and Schedule 80; size 1/4” to 2” IPS; nominal mill lengths of 21’ cut to your projects’ exact length requirements

Alloy 6105-T5 with an anodized finish; size range 3/4” to 2” IPS; nominal mill lengths of 12’ and 24’ cut to your projects’ exact length requirements

Durable, corrosion preventing polyester coating applied to already galvanized/ anodized products; available in any RAL color

Pre-assembled modules for a simple and quick assembly ensuring constant barrier height. Available in a variety of sizes and styles to suit individual project requirements

Panels come in a variety of materials, sizes, and finishes. Material can be provided with a galvanized or powder coat finish, or in bare stainless steel. Virtually any custom configuration or material option is available.

A slot on the back of the toeboard accepts a bolt head which prevents the bolt from spinning during assembly. Upright hardware and splice kits for corners and straight sections are also available. Toeboard comes in 24’ lengths or can be custom cut.

Please fill in your details below and we’ll be in touch shortly.